Normally I present a different tube type in each article of the tube of the month series. But in case of some exceptional tubes it is worth revisiting them. In the recent months I could substantially increase my stock of Telefunken EC8020s. Which offers the opportunity to provide some interesting new photo material of my favorite indirectly heated tube.

All technical aspects and plate curves have already been discussed in last years article about this tube. Today I will mainly show more photos.

With my recent acquisitions of EC 8020 tubes I also got a very rare specimen, an early lab sample:

This must be a sample from the Telefunken development lab, when they worked on this tube type. This was probably meant as early samples to key customers to evaluate the new type.

The sticker says: "Confidential lab sample. No guarantee for the availability of more tubes and for the initially published technical data."

The internal structure is very similar to that of the regular EC8020s:

In my collection of EC8020 triodes there are also a few duds. This offers the opportunity to dissect one and show some close up photos of the internal details.

First the glass needs to be broken:

Removing the glass envelope gives a better view onto the construction of the electrodes:

The plate is composed of two extra large and thick pieces for good cooling. They need to be able to dissipate 8 Watts.

A peek between the two parts of the plate, showing the grid and cathode:

When the glass broke and air rushed in, this damaged the cathode surface and ripped some of the very fine grid wires as can be seen in this close up:

remarkable how delicate and fragile the grid wires are. We will see more of that further down.

More views of the internals:

The silvery 'cage' around the actual structures is there for mechanical stabilisation.

The major part of the plate extending to one side is only for cooling.

The small ring on the top held the getter material which is evaporated after evacuation of the air from the envelope. After the getter deposits like a mirror on the upper dome, the ring has no function anymore. Here a close up of the bottom part with the pins removed. This shows how the cage is clamped to the mica supports:

Slightly right to the middle the cathode sleeve can be seen with the heater wire extending out of it. Here a close up:

The heater is wound in a spiral and sprayed with some insulation material to provide isolation to the cathode.

Top mica supports and getter ring removed:

The next photo shows nicely that the majority of the plates is just for cooling. Only a small part is actually 'active' and has the right distance to the cathode and grid.

A close up showing the active part. The heater wire is removed from the cathode sleeve:

Next the two parts of the plate are removed:

Close up to cathode and grid:

The plates. The outsides are coated with graphite for better heat dissipation properties. One side on each plate is bent to create the exact distance to to grid and cathode:

Now a close up showing grid and cathode. This section got damaged when air rushed in after breaking the glass. Part of the cathode surface flaked off and ripped the grid wires.

In the next photo is done with a ruler to give an idea of the size:

The ruler is centimeter based. The distance between the short lines is 1mm. The next photo is zoomed in to show how thin those grid wires are and how close they are wound together:

About 20 grid wires over a distance of 1mm. That's about 50 micron between the grid wires. This is micro electronics from the early 1960ies!

The next photos show another comparison:

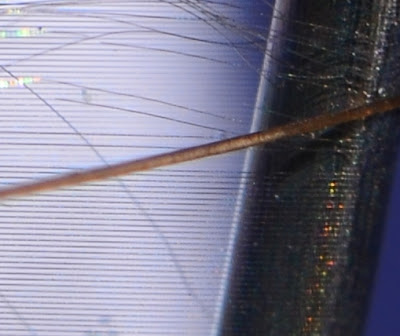

The large 'wire' in front of the grid is actually a human hair!

Here close up:

The diameter of the grid wire is less then a tenth of a human hair!

Another shot with a hair in comparison:

This tube is a truely stunning piece of engineering. Telefunken went to the limits of vacuum tube technology to achieve the unparalleled performance of this tube.

Here a peek at my stash of EC8020s:

I hope you enjoyed this second article about this tube. The EC8020 remains my favorite choice for LCR phonostages and similar small signal applications. I have plans for a fully differential LCR phonostage with this tube. Stay tuned for updates about that.

Best regards

Thomas